Control system

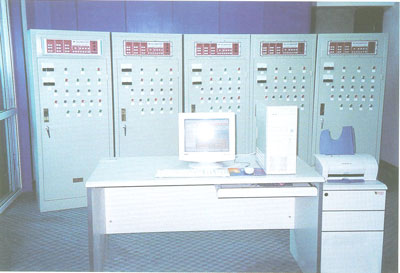

A. Italian Holzmeister-M800B control (Type A)

This control system is a fully automatic control system. It has 80 standard drying programs and program cards with which users can store programs. It has an external probe amplifier (it can be installed 100 meters away from the controller). The system is equipped with 6 probes for detecting moisture content of wood, 2 temperature sensors, 2 equilibrium moisture content sensors as well as powerful computer network function (optional for printing and computer network function).

B. Touch type control system with two pairs of temperature and humidity (type B)

This control system is a semi-automatic control system, and it is the top configuration of the company’s semi-automatic control system. This control system can automatically detect and display the temperature, humidity, moisture content of wood and rotation direction of fans in the kiln, and it can also automatically control the heating system, spraying system, air exchange system and rotation direction of fans based on the set drying schedule (program), thus to control the temperature, humidity and rotation direction of fans in the kiln. By adopting new technologies such as MCU data analysis and PID control etc, the system can realize to inching control the solenoid valve for heating within the temperature setting range (e.g. 60±1℃), thus can greatly reduce the hot inertia when heating, so that the temperature can be controlled within ±0.5℃; The system can realize to control the solenoid valve and damper actuator by three-position type within the humidity setting range, so the problems which is the alternative execution of spraying and air exchange of un-reasonable control can be avoided and the energy consumption can be greatly reduced. There are two positions in the kiln to measure the temperature and humidity and the detected data processed by MCU is more accurate to represent the real condition in the kiln, so the drying rate and drying quality can be greatly improved. The control system is equipped with automatic protection function. The control system will automatically cut off the heating system or air exchange system, thus to avoid the wood seriously checking or deforming because of too high temperature or too low humidity when the temperature sensor or humidity sensor are short-circuited or cut off by accident.

There are certain following auxiliary functions besides the above functions for this control system:

①. The value of the two pairs of temperature and humidity can be displayed; the value of the 6 probes of moisture content of wood can be automatically displayed.

②.The error of the two pairs of temperature and humidity can be corrected.

③. Different control accuracy of temperature and humidity can be set up.

④.Alarm when over-temperature or over-humidity.

C. Instrument type control system with two pairs of temperature and humidity (type C)

This control system is a semi-automatic control system, and it is the general configuration of the company’s semi-automatic control system. This control system can automatically detect and display the temperature, humidity, moisture content of wood and rotation direction of fans in the kiln, and it can also automatically control the heating system, spraying system, air exchange system and rotation direction of fans based on the set drying schedule (program), thus to control the temperature, humidity and rotation direction of fans in the kiln. By adopting new technologies such as MCU data analysis, analog and digital multi filtering and module parameter setting etc, the system can realize to inching control the solenoid valve for heating within the temperature setting range (e.g. 60±1℃), thus can greatly reduce the hot inertia when heating, so that the temperature can be controlled within ±0.5℃; The system can realize to control the solenoid valve for spraying and damper actuator by three-position type within the humidity setting range, so the problems which is the alternative execution of spraying and air exchange because of un-reasonable control can be avoided and the energy consumption can be greatly reduced. There are two positions in the kiln to measure the temperature and humidity and the detected data processed by MCU is more accurate to represent the real condition in the kiln, so the drying rate and drying quality can be greatly improved. The control system is equipped with automatic protection function. The control system will automatically cut off the heating system or air exchange system, thus to avoid the wood seriously checking or deforming because of too high temperature or too low humidity when the temperature sensor or humidity sensor are short-circuited or cut off by accident.

There are certain following auxiliary functions besides the above functions for this control system:

①. The value of the two pairs of temperature and humidity can be displayed; the value of the 6 probes of moisture content of wood can be automatically displayed.

②.The error of the two pairs of temperature and humidity can be corrected.

③. Different control accuracy of temperature and humidity can be set up.

④.Alarm when over-temperature or over-humidity.

D. Instrument type control system with one pair of temperature and humidity (type D)

This control system is a semi-automatic control system, and it is the simple configuration of the company’s semi-automatic control system. This control system can automatically detect and display the temperature, humidity, moisture content of wood and rotation direction of fans in the kiln, and it can also automatically control the heating system, spraying system, air exchange system and rotation direction of fans based on the set drying schedule (program), thus to control the temperature, humidity and rotation direction of fans in the kiln. By adopting new technologies such as MCU data analysis, analog and digital multi filtering and module parameter setting etc, the system can realize to inching control the heating valve within the temperature setting range (e.g. 60±1℃), thus can greatly reduce the hot inertia when heating, so that the temperature can be controlled within ±0.5℃; The system can realize to control the solenoid valve for heating and damper actuator by three-position type within the humidity setting range, so the problems which is the alternative execution of spraying and air exchange because of un-reasonable control can be avoided and the energy consumption can be greatly reduced. The control system is equipped with automatic protection function. The control system will automatically cut off the heating system or air exchange system, thus to avoid the wood seriously checking or deforming because of too high temperature or too low humidity when the temperature sensor or humidity sensor are short-circuited or cut off by accident. But the control system only set one pair of temperature and humidity measuring position in the kiln, and the detected data is not enough to represent the real situation in the kiln, so the control efficiency is not as good as control system A, B and C.

There are certain following auxiliary functions besides the above functions for this control system:

①. The value of the 6 sensors of moisture content of wood can be automatically shown.

②. The error of the one pair of temperature and humidity can be corrected.

③. Different control accuracy of temperature and humidity can be set up.

④. Alarm when over-temperature or over-humidity.

E. Instrument type control systems with one pair of temperature and humidity, and single rotation direction (type E)

This control system is a semi-automatic control system. It can automatically detect and display the temperature, humidity and moisture content of wood in the kiln, and it can also automatically control the heating system, spraying system and air exchange system based on the set drying schedule (program), thus to control the temperature and humidity in the kiln. By adopting new technologies such as MCU data analysis, analog and digital multi filtering and module parameter setting etc, the system can realize to inching control the solenoid valve for heating within the temperature setting range (e.g. 60±1℃), thus can greatly reduce the hot inertia when heating, so that the temperature can be controlled within ±0.5℃; The system can realize to control the spraying valve and damper actuator by three-position type within the humidity setting range, so the problems which is the alternative execution of spraying and air exchange because of un-reasonable control can be avoided and the energy consumption can be greatly reduced. The control system set with automatic protection function. The control system will automatically cut off the heating system or air exchange system, thus to avoid the wood seriously checking or deforming because of too high temperature or too low humidity when the temperature sensor or humidity sensor are short-circuited or cut off by accident. But the control system only set one pair of temperature and humidity measuring position in the kiln, and the acquired data is not enough to represent the real situation in the kiln, and the rotation direction of fans can not also be changed, so the control efficiency is not so good as control system A, B, C and D. This control system can only be used at the mobile metal shell drying equipment.

There are certain following auxiliary functions besides the above functions for this control system:

①. The value of the 6 sensors of moisture content of wood can be automatically detected.

②.The error of the one pair of temperature and humidity can be revised.

③. Different control accuracy of temperature and humidity can be set up.

④. Alarm when over-temperature or over-humidity.

F. Instrument type control system with one pair of temperature and humidity, and only display (type F)

This control system belongs to the manual control system. It can automatically detect and display the temperature, humidity, moisture content of wood and rotation direction of fans in the kiln, but it can automatically not control the heating system, spraying system and air exchange system. This control system can only be equipped with wood drying equipment indirectly heated by furnace air. (But if equipped with mobile metal shell wood drying equipment indirectly heated by furnace air, the instrument for measuring moisture content of wood is optional.)

Heating coils

It is the most popular heating coils in the world with aluminum fins built on stainless steel pipe. The aluminum fins contact closely with the stainless steel pipe. It has advantages such as reliable operation, corrosion resistance, smooth and exquisite

Solenoid valve for heating

The stainless steel solenoid valve for heating produced with German patent acts reliably, and is resistant to corrosion and long service life.

Solenoid valve for spraying

The stainless steel solenoid valve for spraying produced with German patent acts reliably, and is resistant to corrosion and long service life.

Fan

The air ventilation is provided by reversible medium pressure fans with high performance level installed in each chamber above false ceiling of the chamber. The fans can perform with the same efficiency and capacity in both direction and at any revolution rate. Each fan has 6 aluminum swinging blades with perfectly symmetrical shape. The aluminum fan ? 800 mm impellers are fixed directly on to the shaft of the specially designed motors. The motors are tropically insulated to resist high temperature (IP55) and to work without any problems in environments reaching 100% of moisture content.

Damper actuator

The imported Siemens damper actuator has advantages such as small volume, reliable performance and long service life.

Kiln door

The world popular aluminum alloy integrated hanging kiln door is adopted. The whole kiln door is integrated consolidation-type and insulated by polyurethane heat insulator. The kiln door has advantages such as low weight, good heat insulation performance and corrosion-resistant.

Inspection door

It is made of aluminum alloy door frame and insulated by polyurethane heat insulator.

Sealing strip

Sealing strip

It is made of high-temperature purpose-built special-shaped silicon rubber and is ageing-resistant.

Door opening device

It is double-rail hanging-type door opening shelf, and it moves steadily and convenient to lift.

Domestic famous-brand high-temperature hot water pump

Hot water pump

It is made of 6mm thick steel plate after wrapped, lined with high-temperature casting iron and oxidation resistant.

Burning stove

This vertical radiating pipe won’t accumulate dust on the pipe. The soot will deposit on the bottom of the pipe box and very convenient to clean.

Radiating pipe

|